Advancing Winding Technology Precision, Performance, and the Future

Winding techniques play a pivotal role across various industries, often serving as the backbone of countless applications. From electric motors to transformers and beyond, these methods are crucial in ensuring efficiency and functionality. As technology evolves, so too do the strategies used to wind wires and coils. With advancements pushing boundaries, understanding these techniques is more important than ever for professionals seeking an edge in their field.

The winding factor—an essential aspect of this intricate process—can significantly impact performance and reliability. Whether you’re involved in manufacturing or engineering, grasping advanced winding techniques will keep you ahead of the curve. Let’s dive into this fascinating world where precision meets innovation!

The Importance of Winding Techniques in Various Industries

Winding techniques are fundamental to the functionality of many devices and systems. They shape how energy is stored, transformed, and utilized in various applications.

In electrical engineering, for instance, precise winding methods ensure efficient energy transfer within motors and generators. This efficiency directly influences performance and longevity.

The automotive industry also relies heavily on these techniques. Electric vehicles benefit from advanced winding processes that enhance battery pack design and overall vehicle efficiency.

Healthcare equipment like MRI machines or ultrasound devices require specialized coils wound with precision to produce accurate results. Here, the quality of the winding impacts both diagnostics and patient safety.

Even in renewable energy sectors such as wind turbines, optimal winding strategies can maximize power generation potential while minimizing material waste. Each sector underscores a vital truth: effective winding techniques drive innovation across industries.

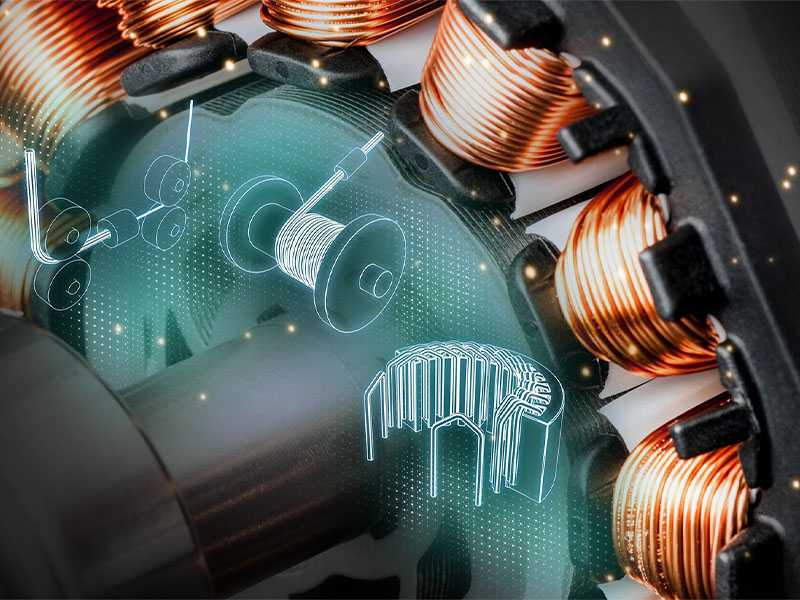

Different Types of Winding Techniques and Their Applications

Winding techniques play a crucial role in various sectors, including electronics and automotive industries. Each technique has unique applications that cater to specific needs.

One common method is the helical winding technique. It’s widely used in transformers, providing efficient magnetic coupling for energy transfer.

Another popular approach is the toroidal winding method. This technique minimizes electromagnetic interference and enhances performance, making it ideal for inductors and filters.

Layered windings are prevalent in motors and generators. They offer improved heat dissipation and better electrical characteristics due to their structured design.

Spiral windings also find their place in flexible circuits, where space-saving solutions are essential. These designs allow for compact configurations without compromising functionality.

Each of these winding methods showcases how tailored techniques can meet the diverse demands across industries while optimizing efficiency and reliability.

Advancements in Winding Technology

Recent advancements in winding technology have transformed the way industries approach coil production. Innovations such as automated winding machines enhance precision and reduce labor costs. These machines can handle complex geometries, ensuring higher efficiency.

Another significant leap is the integration of smart technologies. IoT devices now monitor winding processes in real-time, allowing for immediate adjustments to optimize output quality. This shift enhances transparency and reduces waste.

Industry-Specific Examples of Advanced Winding Techniques

In the automotive industry, advanced winding techniques have revolutionized electric motor manufacturing. Manufacturers are utilizing automated winding systems to create precise coils that enhance efficiency and performance.

The aerospace sector is also reaping benefits from these techniques. Lightweight composite materials are now being wound using robotic arms, ensuring uniformity while significantly reducing weight—an essential factor in flight safety and fuel efficiency.

Renewable energy has seen a surge in the use of innovative winding methods for wind turbine generators. Advanced multilayer winding processes optimize space within compact designs, improving output without compromising structural integrity.

Even medical devices are embracing advancements. Precision-wound components in MRI machines require tight tolerances and specific geometries to function correctly, demonstrating how crucial specialized techniques can be across diverse fields. Each example highlights the critical role of effective winding practices tailored to unique industrial demands.

Benefits and Challenges of Utilizing Advanced Winding Techniques

Advanced winding techniques offer several benefits that can significantly enhance production efficiency. With improved precision and control, manufacturers can produce components that meet stringent quality standards. This leads to reduced waste and more reliable products.

Cost savings are another key advantage. These techniques can optimize material usage and minimize labor costs, ultimately boosting the bottom line for businesses.

However, integrating advanced winding methods isn’t without challenges. The initial investment in technology can be substantial. Companies may need to retrain their workforce to adapt to new processes and equipment.

Furthermore, not all industries will benefit equally from these innovations. Some applications might encounter compatibility issues with existing machinery or face regulatory hurdles regarding new materials or designs.

Balancing these benefits against potential obstacles is crucial for companies looking to innovate in their winding processes while ensuring they remain competitive in an evolving market landscape.

Future Predictions for the Evolution of Winding Technology

The future of winding technology is poised for remarkable transformations. As industries demand more efficiency, innovative materials and methods will emerge.

Integrating artificial intelligence into winding processes will likely enhance precision. Machines could adapt in real-time, optimizing the winding factor based on specific material properties. This adaptability may lead to decreased waste and improved product quality.

Furthermore, advancements in automation will streamline labor-intensive tasks. Robotics can take over repetitive operations while human workers focus on complex problem-solving.

Sustainability also plays a significant role in this evolution. Eco-friendly materials and energy-efficient machines are becoming essential as regulations tighten around environmental impact.

With the rise of smart manufacturing, data analytics will influence every step of production. The ability to gather insights from machine performance can drive continuous improvement in winding techniques across various sectors.

Conclusion

The evolution of winding technology has significantly transformed various industries, making it essential to understand its importance. Winding techniques play a crucial role in optimizing the performance and efficiency of electrical devices, motors, and transformers.