Ultimate Guide to 623-483-04 Screws: Everything You Need to Know

Introduction

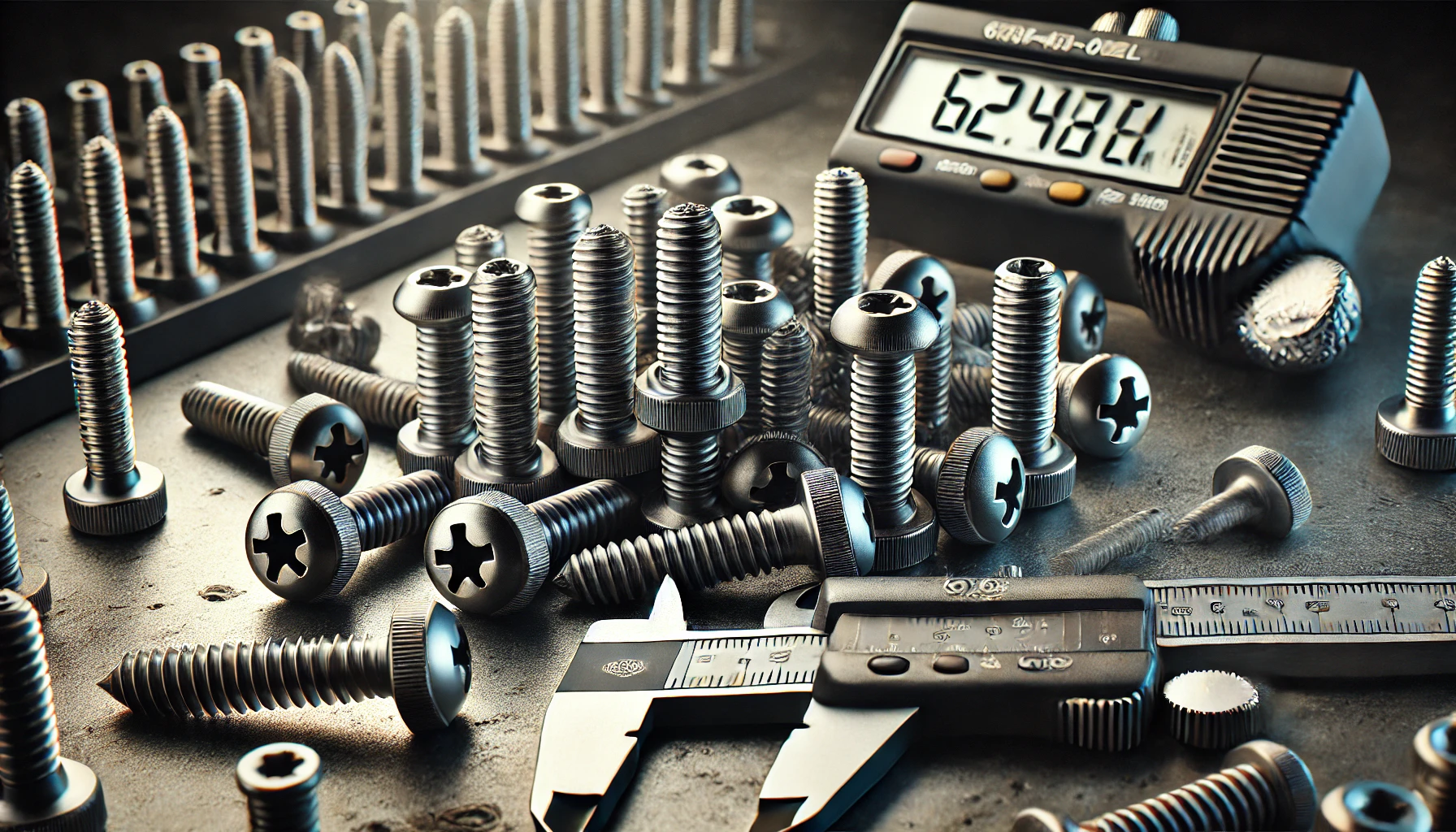

The 623-483-04 screw is more than just a fastener—it’s a high-performance component used across a wide range of demanding industries. Whether you’re an engineer, technician, or DIY enthusiast, understanding the design, specifications, and application of this particular screw can make a significant difference in your project’s outcome. This guide provides a detailed, easy-to-understand explanation of 623-483-04 screws and why they are trusted for precision, durability, and strength.

Technical Specifications

The 623-483-04 screw is known for its robust build and advanced engineering. Typically crafted from high-grade A2-70 stainless steel, this screw offers both strength and resistance to corrosion. It features a 6-lobe (Torx) head, which helps prevent stripping during installation and allows for higher torque transfer.

Common Technical Details:

| Feature | Specification |

| Material | A2-70 Stainless Steel |

| Head Type | 6-Lobe (Torx) |

| Thread Type | Metric |

| Finish Options | Zinc, Black Oxide |

| Tensile Strength | Up to 700 MPa |

| Diameter Range | M3, M4, M5 |

| Standard Compliance | DIN, ISO, ASTM |

These specifications ensure reliability under both mechanical stress and environmental exposure.

Design Features

One of the most notable features of the 623-483-04 screws is the six-lobed Torx head. This unique design offers several mechanical advantages over traditional screws. The Torx head allows for precise torque application without damaging the screw head, making it ideal for precision engineering and repeat installations.

The threading is engineered for smooth engagement and strong grip. It reduces the risk of loosening due to vibrations and is compatible with a wide variety of pre-tapped holes and nuts. Additionally, the screw is available in different coatings, such as zinc or black oxide, which enhance both its aesthetic and protective qualities.

Advantages of 623-483-04 Screws

The 623-483-04 screw excels in various areas:

- Superior Torque Transfer: The 6-lobe design ensures maximum contact with the driver bit, enabling better torque application without slippage.

- Durability: Made from stainless steel, these screws resist rust, oxidation, and wear over time.

- Versatility: Suitable for multiple environments including high-humidity and high-stress mechanical applications.

- Reduced Cam-Out: Unlike Phillips screws, Torx heads greatly minimize the risk of driver slippage.

- Precision Fit: Ideal for tight tolerances and exact alignment.

Industry Applications

The versatility and reliability of 623-483-04 screws make them a staple in multiple industries.

Key Application Areas:

Automotive

Used in dashboards, engine components, and trim panels, these screws withstand mechanical vibrations and thermal fluctuations.

Aerospace

The aerospace industry relies on 623-483-04 screws for assemblies that demand high strength, lightweight, and resistance to extreme temperatures.

Electronics

In devices like smartphones, tablets, and laptops, these screws offer a secure and lasting fastening without damaging sensitive components.

Construction

Builders use them for metal frameworks, structural panels, and high-stress joint reinforcements due to their strength and corrosion resistance.

Marine

Their resistance to rust makes them ideal for marine environments, where salt and moisture are persistent challenges.

Installation Guidelines

Proper installation ensures the full benefits of using 623-483-04 screws. Begin by selecting the right size and type of Torx driver. Always match the tool to the screw head for a secure fit.

Installation Tips:

- Use a Pilot Hole: For hard materials, pre-drill a hole slightly smaller than the screw diameter to prevent material splitting.

- Apply the Right Torque: Over-tightening can damage threads or the material. Use a torque driver for precision.

- Alignment: Make sure the screw enters perpendicular to the surface to avoid angled insertion and potential loosening.

- Clean Work Area: Remove debris or dust to ensure clean contact between surfaces.

Following these steps will improve fastening integrity and product longevity.

Maintenance and Inspection

Regular inspection is key in high-performance applications. Check for signs of rust, wear, or loosening. Screws in critical systems like aerospace or automotive assemblies should be part of scheduled maintenance protocols.

Replace screws that show visible damage or no longer hold torque effectively. Maintaining a log of inspections can help prevent failures in safety-critical environments.

Comparative Analysis

When compared to traditional screws such as Phillips or flathead types, the 623-483-04 stands out in several key areas:

| Feature | 623-483-04 Screw | Phillips/Flathead |

| Torque Transfer | High | Moderate |

| Cam-Out Resistance | Excellent | Low |

| Corrosion Resistance | High (with coatings) | Moderate |

| Application Range | Broad (Aerospace, etc) | Limited |

| Cost | Moderate | Low |

While the 623-483-04 may have a higher initial cost, the long-term benefits and reliability justify the investment.

Procurement and Availability

These screws are widely available from specialized fastener suppliers and aerospace component distributors. Look for authorized vendors to ensure you’re getting certified, high-quality products.

When buying in bulk, confirm the specifications, check for batch certifications, and inquire about coating options. Many suppliers offer custom packaging and labeling for industrial buyers.

Additional FAQs (Value-Added)

- Can 623-483-04 screws be used with plastic materials?

Yes, but it’s recommended to use a pilot hole and lower torque settings to avoid cracking the plastic. - Are 623-483-04 screws available in titanium?

Some specialty manufacturers may offer titanium versions for aerospace or medical applications. - Is it safe to use these screws in outdoor environments?

Absolutely. Their corrosion-resistant coating makes them suitable for both indoor and outdoor use. - Do I need thread lockers for these screws?

Thread lockers can be used in high-vibration environments to ensure added security. - What’s the shelf life of these screws?

When stored in a dry, cool environment, they can last indefinitely without degrading.

Conclusion

623-483-04 screws offer a robust, reliable, and versatile fastening solution across multiple industries. With features like a Torx head, stainless steel construction, and advanced coatings, they are engineered for performance and longevity. Whether you’re working on a DIY project or managing an aerospace assembly, understanding and properly using these screws ensures better results and long-term durability. This guide is your go-to reference for selecting, using, and maintaining 623-483-04 screws with confidence.

Recommended Articles

- Yon Bèt Debaz: Meaning, Origin, Usage, and Cultural Context Explained

- Emergency Surgery: A Complete Guide to Life-Saving Surgical InterventionIntroduction to Emergency Surgery

- The Ultimate Guide to Clickbaitosaurus: Understanding, Identifying, and Defeating the Beast of Digital Deception

- The Ultimate Guide to the Songbird Serenade AI Voice Model

- NBA 2K23 Chuma Okeke Cyberface: The Ultimate Guide to His Realistic In-Game Look