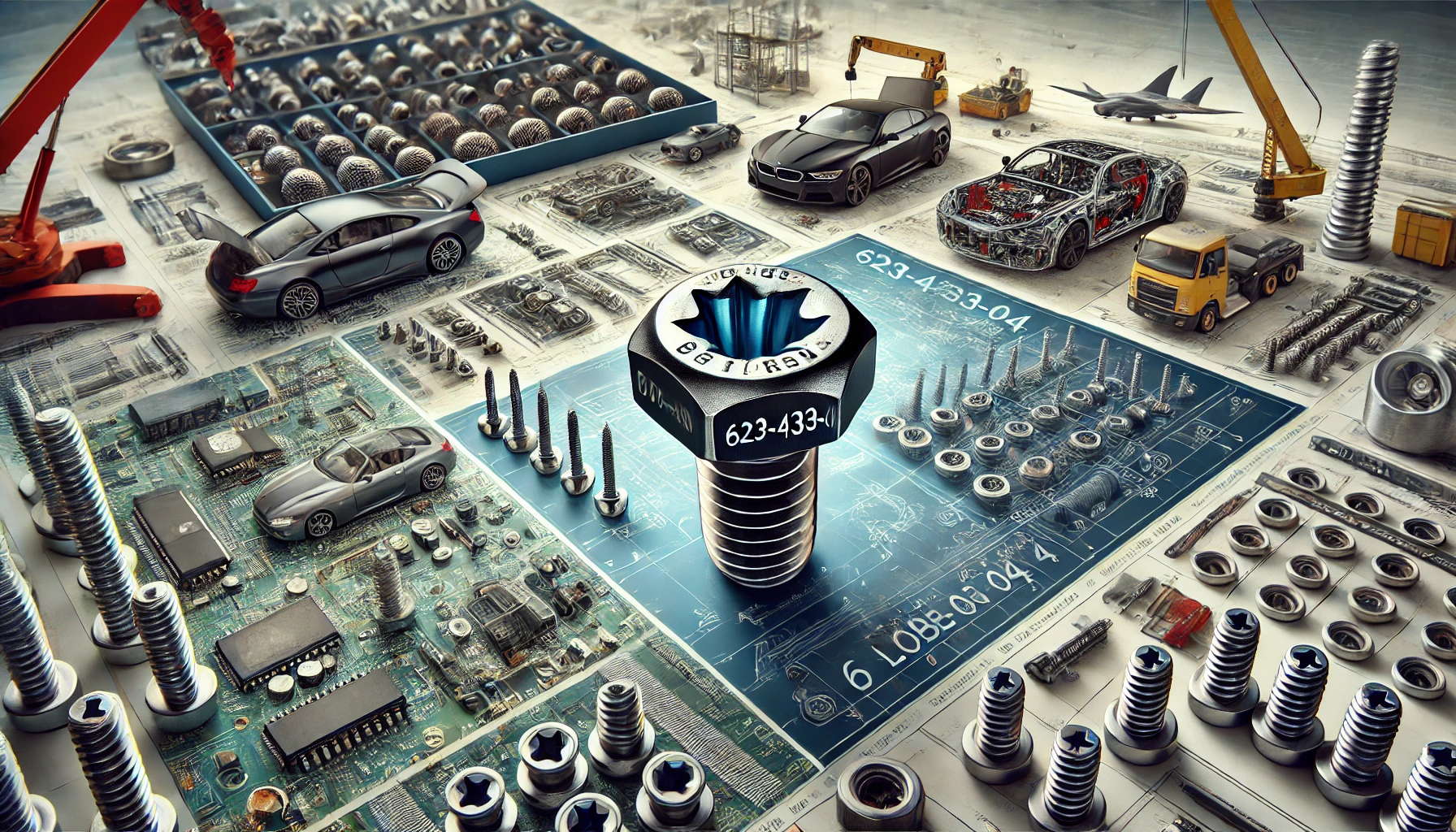

The Complete Guide to the 623-483-04 6 Lobe Screw

Introduction

The world of fasteners is vast, but among them, the 623-483-04 6 lobe screw stands out for its unique design, strength, and functionality. Whether you are a professional in construction, electronics, or automotive industries, understanding this screw can enhance the quality and reliability of your projects. This guide is crafted to walk you through every important aspect of this component, making it easier to select, use, and benefit from it.

Understanding the 623-483-04 6 Lobe Screw

The 623-483-04 6 lobe screw is a type of fastener characterized by its six-point star-shaped head, commonly known as a Torx drive. This design enables superior torque transfer and reduces the risk of cam-out, a common issue with traditional Phillips or flathead screws. The unique head style allows for a tighter and more secure fit, which is crucial in applications where safety and durability are paramount.

From its name, “623-483-04” typically refers to a part or SKU code that identifies its size, threading, and material specifications. It’s a common component in high-performance assemblies.

Key Features and Advantages

One of the most important advantages of the 623-483-04 6 lobe screw is its torque-handling capability. Its design allows for better grip with compatible drivers, ensuring minimal slipping during application. This not only preserves the integrity of the screw but also protects the material into which it is fastened.

Another significant feature is its resistance to wear and corrosion. When manufactured from stainless steel or treated with anti-corrosive coatings like zinc or black oxide, these screws become ideal for both indoor and outdoor environments.

The screw’s precision threading ensures secure and stable fastening, even under intense vibrations. This makes it a popular choice in the automotive and aerospace sectors.

Applications of the 623-483-04 6 Lobe Screw

The versatility of the 623-483-04 6 lobe screw means it finds use in a wide variety of industries:

Automotive

These screws are essential in securing components such as dashboards, engine parts, and trim panels. Their strength and resistance to vibration make them ideal for vehicle manufacturing and repair.

Electronics

In gadgets and devices like smartphones, laptops, and industrial machinery, the compact size and firm hold of 6 lobe screws provide the stability needed for sensitive components.

Aerospace

With strict safety and performance requirements, aerospace applications rely on screws that can endure high stress and extreme temperatures, making the 623-483-04 screw a trusted choice.

Construction and Furniture

For heavy-duty furniture and metal framework in construction, these screws provide a strong joint and are easy to drive into different materials.

Technical Specifications

Understanding the specs of the 623-483-04 6 lobe screw helps in selecting the right variant for your needs:

| Specification | Details |

| Head Type | 6 Lobe (Torx) |

| Material | Stainless Steel / Alloy Steel |

| Coating | Zinc-plated / Black Oxide |

| Thread Type | Metric / Imperial Options |

| Common Sizes | M3, M4, M5 (varies by supplier) |

| Drive Size | T10, T15, T20 (Torx driver) |

Installation and Removal Guidelines

Installing the 623-483-04 6 lobe screw is straightforward, but following best practices ensures a durable and secure fit. Always use a matching Torx driver to prevent damage to the screw head. Pre-drilling may be necessary when working with hardwoods or metals to avoid cracking or slipping.

When removing the screw, apply steady pressure with a Torx driver and avoid using worn-out tools to prevent stripping. For stubborn or rusted screws, apply lubricant and allow it to sit before attempting removal.

Maintenance and Care

To ensure longevity, these screws should be periodically inspected in high-stress environments. If exposed to moisture or chemicals, clean them with a dry cloth and reapply protective coatings if needed. Store unused screws in a dry, cool place to prevent oxidation.

Comparing the 623-483-04 Screw with Other Fasteners

| Feature | 623-483-04 6 Lobe | Phillips Head | Hex Head |

| Torque Transfer | High | Moderate | High |

| Cam-out Resistance | Excellent | Poor | Good |

| Tool Engagement | Firm | Slips easily | Varies |

| Application Ease | Easy | Moderate | Easy |

| Durability | High | Average | High |

Choosing the Right 623-483-04 6 Lobe Screw

When selecting this screw, consider the working environment (e.g., humidity, heat), material compatibility (e.g., metal, wood, plastic), and the load or stress the joint will bear. Customized versions with special coatings or lengths may also be available for specific needs.

Sourcing and Purchasing

Reliable sourcing is crucial for maintaining quality in your projects. Look for certified suppliers who provide specifications and testing reports. Bulk buying can reduce costs significantly, and many suppliers offer fast delivery and technical support.

Additional FAQs

- Is the 623-483-04 screw compatible with power tools?

Yes, it is compatible with both manual and powered Torx drivers. - What happens if the screw rusts?

Rust can reduce performance. Use anti-rust treatments or choose stainless steel variants. - Is it suitable for high-temperature applications?

Yes, especially when made from high-grade alloys. - How can I identify the exact 623-483-04 model?

Refer to the manufacturer’s datasheet or packaging label for dimensions and specs. - Do I need a washer with this screw?

Depending on the application, a washer may improve load distribution and prevent material damage.

Conclusion

The 623-483-04 6 lobe screw is a highly reliable and versatile fastener, offering superior grip, durability, and performance across multiple industries. Its specialized design ensures safety and strength in demanding environments. By understanding its features, applications, and proper usage, professionals and DIYers alike can make informed decisions that lead to more secure and long-lasting assemblies.

Recommended Articles

- Complete Guide to R. STAHL Explosion-Proof Floodlight – Part-No: 6121/5312-640-01

- Johan Espinosa Software Libre: A Complete Guide to His Mission and Legacy

- Emergency Surgery: A Complete Guide to Life-Saving Surgical InterventionIntroduction to Emergency Surgery

- The Ultimate Guide to Clickbaitosaurus: Understanding, Identifying, and Defeating the Beast of Digital Deception

- The Ultimate Guide to the Songbird Serenade AI Voice Model